The earliest engineers have been drawing glass into fibers since Roman times. It wasn’t until the 1790s that the first optical telegraph was created by the Chappe brothers, who developed a series of lights mounted on towers that relayed messages from one tower to the next. Further incarnations were steadily introduced through the mid-1800s, as scientists proved that light signals could be bent by sending a light through a curved stream of water. Thanks to initial discoveries by the famed Alexander Graham Bell, in the 1970s and 1980s, the widespread use of fibers for communications infrastructure was adopted. Today, after years of development, optical fiber systems are even more robust and powerful than ever before.

When we picture glass, the first thing that comes to mind is a transparent glass window. However, as glass gets thicker, the number of impurities increase and it becomes more clouded. Optical fibers do not measure much larger than a human hair- around 1/8mm or 0.005 inches in diameter, ensuring the clearest glass possible. Some fiber optics companies report that if you stood on an ocean made of fiber optic glass miles deep, you could see the bottom.

A fiber optic cable starts out as a large glass tube. This is first cleaned in a corrosive bath to ensure that any dirt and oil residue are removed from the tube. The preform blank is manufactured through modified chemical vapor deposition (MCVD). A solution of silicon chloride and germanium chloride is pumped with oxygen, and the gas vapor byproduct is collected in a synthetic tube. As the tube is rotated, a torch heats the outside, causing the silicone and germanium to react with the oxygen, and fuse together to form glass. It is vital that the lathe be turned uniformly for a consistent coating. The intense heat eventually causes the tube to collapse on itself and become a solid rod, transforming into the initial structure of the optical fiber.

After creating the blank, it vertically installed into a fiber drawing tower. The extreme heat of the furnace in the tower (about 2200 degrees Celsius) melts the blank until it drips and falls downward like molasses dripping from a spoon, cooling on the way and forming a thread. A large glob is attached to the end of the glass fiber, stretching and pulling it even further to the ideal thickness. A series of pulleys measure the tension on the fiber as it is being drawn. Then the fiber passes through UV lamps that bake on a protective coating to protect against dust and other contaminants.

Each fiber cable must be tested for a variety of factors, including tensile strength, refractive index profile, operating temperature, and attenuation. Finally, the fiber is rolled onto a drum, and either shipped out as is, or inserted into a cable. They can then be distributed to telephone companies, network providers, or distributors like SanSpot.

Tuesday, December 30, 2014

Tuesday, December 23, 2014

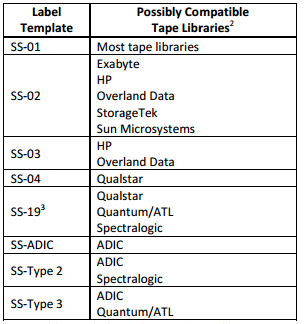

Product Spotlight: LTO Tape Barcode Labels

Although the options for data storage are far more numerous than they were twenty years ago, many LTO Ultrium tape users still ardently defend the technology for their data storage needs. When first developed in the late 1990s as a partnership between Hewlett Packard, IBM, and Seagate, Linear Tape-Open immediately defined the super tape market. With multiple generations of LTO tape capacities that reached as high as 1.5 terabytes of data.

With LTO tapes holding such vital information, it is important that your data library is well organized. SanSpot has a series of highly customizable LTO tape labels to be sure that your LTO tapes are easy to identify, sort, and categorize, and can apply for data, cleaning, or diagnostic cartridges.

SanSpot’s selection of three color palettes (hot, warm, and cool) for the human readable section make organizing for easy sight recognition even simpler. Our hot color palette is the most popular, but custom color palettes are also available upon request.

If you are not 100% sure which labels are right for your library, we are happy to help you in a variety of ways. First, take a glance at our helpful table above to compare our template styles with your tape types. You can scan the label stickers you are currently using for LTO tapes and email them to SanSpot to help to select or customize the perfect labels for your library.

Be sure to visit out LTO Label Reference Guide for more info.

With LTO tapes holding such vital information, it is important that your data library is well organized. SanSpot has a series of highly customizable LTO tape labels to be sure that your LTO tapes are easy to identify, sort, and categorize, and can apply for data, cleaning, or diagnostic cartridges.

SanSpot’s selection of three color palettes (hot, warm, and cool) for the human readable section make organizing for easy sight recognition even simpler. Our hot color palette is the most popular, but custom color palettes are also available upon request.

If you are not 100% sure which labels are right for your library, we are happy to help you in a variety of ways. First, take a glance at our helpful table above to compare our template styles with your tape types. You can scan the label stickers you are currently using for LTO tapes and email them to SanSpot to help to select or customize the perfect labels for your library.

Be sure to visit out LTO Label Reference Guide for more info.

Tuesday, December 16, 2014

The Fiber Optic Revolution: Why Fiber Optics Are Replacing Copper

While the technology advancements in our personal devices and processing systems have been rapid and profound, the progression in cabling and transmission mediums has been significantly slower. Although copper wire manufacturers have made some respectable improvements to their technology in recent years, they cannot compete with the more significant advancements and advantages of fiber optic systems.

While the technology advancements in our personal devices and processing systems have been rapid and profound, the progression in cabling and transmission mediums has been significantly slower. Although copper wire manufacturers have made some respectable improvements to their technology in recent years, they cannot compete with the more significant advancements and advantages of fiber optic systems.Cost: Miles of optical cables can be made for significantly cheaper than copper cables for an equivalent strength and length. Whether you are the direct B2B purchaser of the cables or the end user, you will experience a cost savings. Additionally, the transmitters that are used with optical fibers are low power as opposed to the high voltage electrical transmitters that copper wires require. Providers are able to pass these energy savings along to their consumers to remain competitive. And while set up costs for modern optical fiber systems can be greater in the short term, they are less costly to maintain, experience significantly less downtime, and typically require less networking hardware.

Bandwidth: Optical fiber is capable of readily transmitting high bandwidth data over moderate distances when compared to copper alternatives. The Telecommunications Industry Association reports that a Category 6A Cable can manage a bandwidth of 600 MHz over 100 meters, and would be able to carry the equivalent of 18,000 phone calls at one time. By comparison, Multimode Fibers have a bandwidth of over 1000 MHz, and could carry 30,000 simultaneous phone calls.

Distance: The reduction in your signal strength during transmission is known as the attenuation. Since fiber optic signals are made of light, very little signal loss is likely to occur during transmission, allowing data to move at higher speeds for longer distances. Additionally, a twisted pair copper cable has a 100 meter distance limitation that fiber optics are not inhibited by. Typically, fiber distances can stretch from 300 meters to 40 kilometers, or about 25 miles.

Design: The physical advantages of fiber over copper are irrefutable. With a lightweight, thin, and durable design, it is easier to transport and handle. Its small size not only means that it takes up less room, but allows for a greater number of lines to be installed, either above or below ground.

Safety: Fiber optic cables are dielectric materials, meaning that it is an electric insulator. On the other hand, copper wires carry a current, and could be the cause of a potential fire hazard if a break occurs. There have even been cases of thieves catching on fire when attempting to steal copper wires.

When first invented, copper wire was able to connect us to information we had been unable to reach previously. Now, thanks to fiber optic systems, the globe is being linked together to an unprecedented degree, allowing the world to experience the next generation of networks. Although some industries have been slow to adapt, the benefits of optical fiber technology promises many long-term benefits.

Subscribe to:

Posts (Atom)